Unbalance Vibratory Motor

Introduction :

An Unbalance Vibratory Motor is a powerful and compact device used to generate vibration for various industrial applications. It works on the principle of creating an unbalanced force using rotating eccentric weights mounted on the motor shaft. This vibration is then transmitted to a machine or structure to facilitate operations like feeding, screening, compacting, and conveying.

Orton has a wide range of UNBALANCE MOTOR VIBRATORS to meet the requirement of various industries wherein material handling plays a major role.

These vibrators are suitable for mounting on bin and storage silo, vibrating feeders, tables & screens & many other applications ORTON UNBALANCE MOTOR vibrators are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phase, 50 cycles. A.C. Supply. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available viz, : 3000, 1500, 1000, 750 vibrations per minute. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet this requirements.

When used as a single unit, they impact circular vibrations. If directional vibrations are needed, two vibrators running in the opposite direction should be use.

These vibrators help to empty, dose, convey, loosen, test, clean, screen, compact, distribute, feed etc., & therefore have a very wide application in Mining, Fertilizer, Chemical , Pharma & Food Industry etc.

Unbalance motor vibrators are used where mechanical vibrations are required. There vibrations can be in the form of pure rectilinear vibrations for conveying / screening the material in vibratory feeders / screens / tables etc. For obtaining rectilinear vibrations, two unbalance motor vibrators rotating in the opposite directions are used.

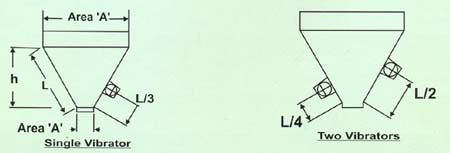

Unbalance motor vibrators are also used as bin vibrator wherein the hopper / bin walls are vibrated so as to prevent choking of the material at the discharge portion of the hopper. The location of the motor vibrator is extremely important & is generally located in the lower convergent part of the hopper is as shown in the sketch depicated below. For such applications, motors with high rpm (approx 3000 rpm) are used as high frequency vibrations are to be generated. The vibrator selection depends upon various factors such as wall thickness, weight to be vibrated etc. Customer to specify inlet & outlet diameter of hopper, thickness of hopper, height of hopper, material inside the hopper, bulk density of the material.

Use of Unbalance Vibratory Motor :

An Unbalance Vibratory Motor is a type of electric motor with an unbalanced weight attached to the rotor,which generates vibration during rotation. These vibrations are used to move, compact, or separate materials in industrial processes.

Key Uses of Unbalance Vibratory Motors :

- Material Handling Systems : Used in vibrating feeders, conveyors, and screens. Facilitates flow of bulk materials like coal, ores, grains, etc.

- Vibrating Screens : For separation, grading, and sorting of materials based on size.

- Compaction Equipment : Helps in compacting powders or materials in containers or molds.

- Vibrating Tables : Used to remove air bubbles in concrete or to settle materials.

- Packaging Machines : Aids in proper distribution and settling of powders or granules in packaging.

- Hopper Discharge Systems : Prevents material clogging by promoting smooth discharge.

- Foundry Applications : Used in vibrating sand reclamation systems and mold compaction units.

- Construction Equipment : Used in concrete block-making machines and surface finishing equipment.

Unbalance Vibratory Motor application industries

Unbalance Vibratory Motors are used in various industries for material handling, separation, compaction, and screening tasks due to their ability to generate controlled vibrations.

Application Industries for Unbalance Vibratory Motors:

- Mining & Mineral Processing : Screening, sizing, dewatering, and feeding of ores and minerals.

- Construction & Building Materials : Vibratory compactors, concrete vibrators, and material transport systems.

- Chemical Industry : Vibrating conveyors, screens, and feeders for powders, granules, and bulk materials.

- Food & Beverage : Used in vibrating sieves, feeders, and conveyors for sorting and processing food grains, spices, etc.

- Pharmaceuticals : Precise vibration equipment for screening and feeding powders and granules in clean environments.

- Fertilizer Industry : For uniform feeding and screening of granulated fertilizers.

- Cement & Aggregates : To aid in the handling, screening, and feeding of cement, sand, and gravel.

- Foundries : Used in vibrating shakeouts, sand reclaimers, and vibratory compaction tables.

- Ceramics & Glass : In vibrating screens and conveyors for clay, silica, and glass materials.

- Recycling & Waste Management : For separating and classifying materials during recycling processes.

- Metallurgical Industry : For furnace charging, vibrating tables, and material transportation